Services We Offer

How can we help you?

1- System Review

Our team of experts will perform a plant system review and develop strategies to improve production facilities. System reviews are tailored to a specific client needs. Whether it’s production, inspection or even troubleshooting, we have the tools and knowledge to properly evaluate the existing facilities. Our engineers will perform a detailed system review on site and work with the operation and maintenance teams to resolve any issues discovered. Upon completion of the system review, a detailed report, including a heat and material operational balance, will be submitted to help improving plant’s production.

What are the benefits:

- Increase in production

- Increase in operation uptime

- Product quality and purity

- Reduction in power consumption

- Equipment efficiency and functionality.

Process Design

MEGA Engineering Industries has acquired vast knowledge in process design, obtained over decades of working in the heavy industries (iron & steel and cement). We utilize this experience to design the most efficient, cost-effective, and user-friendly systems for plant facilities.

MEGA Engineering Industries strives to continuously implement the latest available technology to ensure our customer satisfaction. We utilize various software and bench scale testing to provide a proper working system. We pride ourselves on our broad knowledge across various disciplines which allow us to provide a complete package to our customers.

1- System Review

Our team of experts will perform a plant system review and develop strategies to improve production facilities. System reviews are tailored to a specific client needs. Whether it’s production, inspection or even troubleshooting, we have the tools and knowledge to properly evaluate the existing facilities. Our engineers will perform a detailed system review on site and work with the operation and maintenance teams to resolve any issues discovered. Upon completion of the system review, a detailed report, including a heat and material operational balance, will be submitted to help improving plant’s production.

What are the benefits:

- Increase in production

- Increase in operation uptime

- Product quality and purity

- Reduction in power consumption

- Equipment efficiency and functionality.

Process Design

MEGA Engineering Industries has acquired vast knowledge in process design, obtained over decades of working in the heavy industries (iron & steel and cement). We utilize this experience to design the most efficient, cost-effective, and user-friendly systems for plant facilities.

MEGA Engineering Industries strives to continuously implement the latest available technology to ensure our customer satisfaction. We utilize various software and bench scale testing to provide a proper working system. We pride ourselves on our broad knowledge across various disciplines which allow us to provide a complete package to our customers.

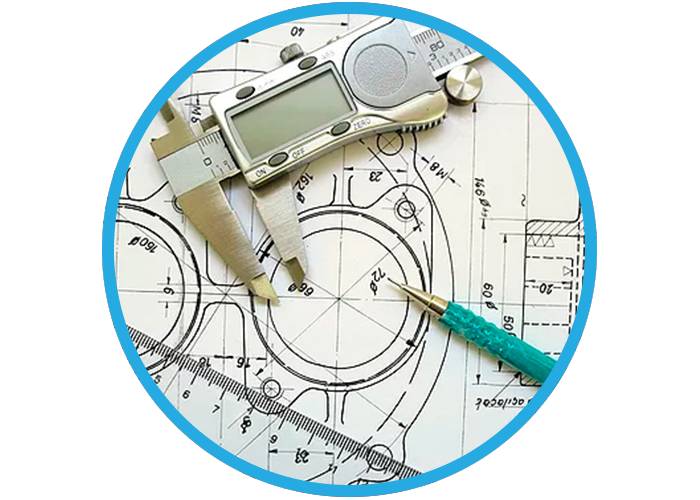

2- Plant Design & Engineering

MEGA Engineering Industries has acquired vast knowledge in process design, obtained over decades of working in the heavy industries (iron & steel and cement). We utilize this experience to design the most efficient, cost-effective, and user-friendly systems for plant facilities.

MEGA Engineering Industries strives to continuously implement the latest available technology to ensure our customer satisfaction. We utilize various software and bench scale testing to provide a proper working system. We pride ourselves on our broad knowledge across various disciplines which allow us to provide a complete package to our customers.

2- Plant Design & Engineering

MEGA Engineering Industries has acquired vast knowledge in process design, obtained over decades of working in the heavy industries (iron & steel and cement). We utilize this experience to design the most efficient, cost-effective, and user-friendly systems for plant facilities.

MEGA Engineering Industries strives to continuously implement the latest available technology to ensure our customer satisfaction. We utilize various software and bench scale testing to provide a proper working system. We pride ourselves on our broad knowledge across various disciplines which allow us to provide a complete package to our customers.

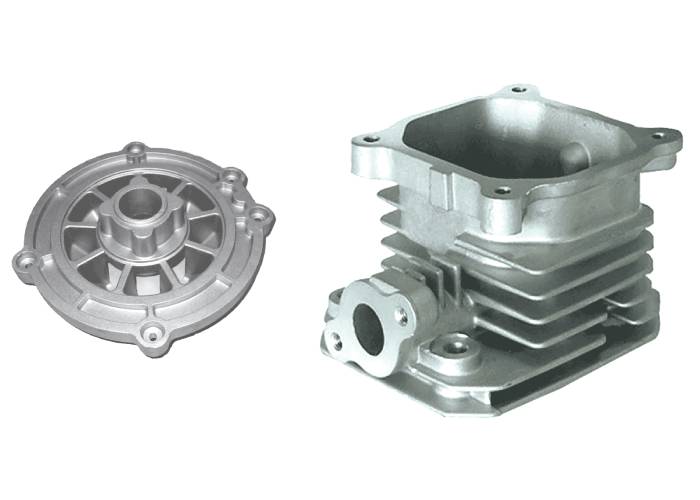

3- Equipment Design & Fabrication

MEGA Engineering Industries is always exploring new solutions when it comes to equipment design. Mechanical design and material selection are integral to our process. It is important to consider how these components work together to achieve the best design.

When working on a project, we always keep our clients’ needs in mind. As energy efficiency becomes a greater concern in our industry, so do sustainable materials choices and budget-friendly options. We closely collaborate with clients to create equipment design that is simple for the end users. We constantly look for new opportunities to improve our designs and enhance user experience.

All our equipment is mechanically designed and manufactured according to the latest industry standards. All our equipment is produced in our production facility or by one of our trusted suppliers of specialty equipment.

3- Equipment Design & Fabrication

MEGA Engineering Industries is always exploring new solutions when it comes to equipment design. Mechanical design and material selection are integral to our process. It is important to consider how these components work together to achieve the best design.

When working on a project, we always keep our clients’ needs in mind. As energy efficiency becomes a greater concern in our industry, so do sustainable materials choices and budget-friendly options. We closely collaborate with clients to create equipment design that is simple for the end users. We constantly look for new opportunities to improve our designs and enhance user experience.

All our equipment is mechanically designed and manufactured according to the latest industry standards. All our equipment is produced in our production facility or by one of our trusted suppliers of specialty equipment.

4- On-Site Modification & Installation

Our staff members are experts at launching, evaluating, and optimizing plants. We work with our clients to improve production and operations. Our modification process starts with a comprehensive review of the current systems, as well as process and equipment reviews. We look at overall plant engineering, equipment design, and manufacturing processes to advise any necessary adjustments. Modifications and installation jobs can be carried out as turnkey by our own team of field engineers, mechanics and welders or we manage a local team of qualified personnel to perform the job as efficient as possible to our specification and standards.

4- On-Site Modification & Installation

Our staff members are experts at launching, evaluating, and optimizing plants. We work with our clients to improve production and operations. Our modification process starts with a comprehensive review of the current systems, as well as process and equipment reviews. We look at overall plant engineering, equipment design, and manufacturing processes to advise any necessary adjustments. Modifications and installation jobs can be carried out as turnkey by our own team of field engineers, mechanics and welders or we manage a local team of qualified personnel to perform the job as efficient as possible to our specification and standards.

5- Commissioning, Startup and Training

MEGA Engineering Industries offers years of experience in system installation, commissioning and start-up to our clients. Our experience allows a smooth and detailed start-up experience. Our dedicated team will work together with your operations group, training your staff ensuring smooth handover of the system.

Even after we have completed system optimization and left our client facility. MEGA Engineering Industries is dedicated to help our clients troubleshoot operation issues remotely or on-site. Our high level of experience can be offered in a full commissioning package or as stand-alone services.

Our Training Scope:

MEGA Engineering Industries offers a specific training services to our clients in different industries, i.e. Cement, Fertilizers, Iron and steel and Petroleum/O&G, developing technical orientation of both engineers and technicians.

The aim of the training service can be categorized as follows:

- Basic and OJT (On Job Training) based programs keeping staff competent enough to perform the specific technical tasks,

- Specific Gaps Elimination Program (SGEP) for the current staff bridging the gap of knowledge in some technical Tasks “Competency GAPS”,

- Basic Knowledge & Applied Technical Programs based on the type of industry for the concerned people who are seeking to find new job in Cement, Iron & Steel or Petroleum Sector.

5- Commissioning, Startup and Training

MEGA Engineering Industries offers years of experience in system installation, commissioning and start-up to our clients. Our experience allows a smooth and detailed start-up experience. Our dedicated team will work together with your operations group, training your staff ensuring smooth handover of the system.

Even after we have completed system optimization and left our client facility. MEGA Engineering Industries is dedicated to help our clients troubleshoot operation issues remotely or on-site. Our high level of experience can be offered in a full commissioning package or as stand-alone services.

Our Training Scope:

MEGA Engineering Industries offers a specific training services to our clients in different industries, i.e. Cement, Fertilizers, Iron and steel and Petroleum/O&G, developing technical orientation of both engineers and technicians.

The aim of the training service can be categorized as follows:

- Basic and OJT (On Job Training) based programs keeping staff competent enough to perform the specific technical tasks,

- Specific Gaps Elimination Program (SGEP) for the current staff bridging the gap of knowledge in some technical Tasks “Competency GAPS”,

- Basic Knowledge & Applied Technical Programs based on the type of industry for the concerned people who are seeking to find new job in Cement, Iron & Steel or Petroleum Sector.

6- Evaluation & Monitoring

MEGA Engineering Industries provides satisfactorily experience well beyond the commissioning and start-up phase. Once our staff is offsite, our efforts do not stop.

MEGA Engineering Industries recognizes there will be many minor upsets in operation at some points. Our team is dedicated to help our clients troubleshoot these issues remotely or on-site when needed.

6- Evaluation & Monitoring

MEGA Engineering Industries provides satisfactorily experience well beyond the commissioning and start-up phase. Once our staff is offsite, our efforts do not stop.

MEGA Engineering Industries recognizes there will be many minor upsets in operation at some points. Our team is dedicated to help our clients troubleshoot these issues remotely or on-site when needed.

How can we help you?

System Review

Our team of experts will perform a plant system review and develop strategies to improve production facilities. System reviews are tailored to a specific client needs. Whether it’s production, inspection or even troubleshooting, we have the tools and knowledge to properly evaluate the existing facilities. Our engineers will perform a detailed system review on site and work with the operation and maintenance teams to resolve any issues discovered. Upon completion of the system review, a detailed report, including a heat and material operational balance, will be submitted to help improving plant’s production.

What are the benefits:

- Increase in production

- Increase in operation uptime

- Product quality and purity

- Reduction in power consumption

- Equipment efficiency and functionality.

Process Design

MEGA Engineering Industries has acquired vast knowledge in process design, obtained over decades of working in the heavy industries (iron & steel and cement). We utilize this experience to design the most efficient, cost-effective, and user-friendly systems for plant facilities.

MEGA Engineering Industries strives to continuously implement the latest available technology to ensure our customer satisfaction. We utilize various software and bench scale testing to provide a proper working system. We pride ourselves on our broad knowledge across various disciplines which allow us to provide a complete package to our customers.

Plant Design & Engineering

MEGA Engineering Industries specializes in optimized plant design for both existing and new facilities. Our full-service mechanical engineering and design services are available in-house. We work closely with customers to ensure optimization throughout the entire design process. Using the latest 3D technology, our engineers will provide efficient solutions for both system design and facility

Equipment Design &Fabrication

MEGA Engineering Industries is always exploring new solutions when it comes to equipment design. Mechanical design and material selection are integral to our process. It is important to consider how these components work together to achieve the best design.

When working on a project, we always keep our clients’ needs in mind. As energy efficiency becomes a greater concern in our industry, so do sustainable materials choices and budget-friendly options. We closely collaborate with clients to create equipment design that is simple for the end users. We constantly look for new opportunities to improve our designs and enhance user experience.

All our equipment is mechanically designed and manufactured according to the latest industry standards. All our equipment is produced in our production facility or by one of our trusted suppliers of specialty equipment.

On-Site Modification & Installation

Our staff members are experts at launching, evaluating, and optimizing plants. We work with our clients to improve production and operations. Our modification process starts with a comprehensive review of the current systems, as well as process and equipment reviews. We look at overall plant engineering, equipment design, and manufacturing processes to advise any necessary adjustments. Modifications and installation jobs can be carried out as turnkey by our own team of field engineers, mechanics and welders or we manage a local team of qualified personnel to perform the job as efficient as possible to our specification and standards.

Evaluation & Monitoring

MEGA Engineering Industries provides satisfactorily experience well beyond the commissioning and start-up phase. Once our staff is offsite, our efforts do not stop.

MEGA Engineering Industries recognizes there will be many minor upsets in operation at some points. Our team is dedicated to help our clients troubleshoot these issues remotely or on-site when needed.

Commissioning, Startup and Training

MEGA Engineering Industries offers years of experience in system installation, commissioning and start-up to our clients. Our experience allows a smooth and detailed start-up experience. Our dedicated team will work together with your operations group, training your staff ensuring smooth handover of the system.

Even after we have completed system optimization and left our client facility. MEGA Engineering Industries is dedicated to help our clients troubleshoot operation issues remotely or on-site. Our high level of experience can be offered in a full commissioning package or as stand-alone services.

Our Training Scope:

MEGA Engineering Industries offers a specific training services to our clients in different industries, i.e. Cement, Fertilizers, Iron and steel and Petroleum/O&G, developing technical orientation of both engineers and technicians.

The aim of the training service can be categorized as follows:

- Basic and OJT (On Job Training) based programs keeping staff competent enough to perform the specific technical tasks,

- Specific Gaps Elimination Program (SGEP) for the current staff bridging the gap of knowledge in some technical Tasks “Competency GAPS”,

- Basic Knowledge & Applied Technical Programs based on the type of industry for the concerned people who are seeking to find new job in Cement, Iron & Steel or Petroleum Sector.